NEW SUSTAINABLE SOLUTION

FOR FLEXIBLE PACKAGING

WatPac

INNOVATIVE PACKAGING

BASED ON WATER-SOLUBLE MATERIALS

«WatPac»

CONCEPTION

Concept «WatPac» is based on the usage of a functional water-soluble layer.

The packaging materials that manufactured under «WatPac»’s brand are RECYCLABLE, RE-PULPABLE, NON-TOXIC and MARINE SAFE. They are capable of being processed in all standard waste streams. In addition they are food safe and approved for a direct food contact.

This packaging is really suits for the Circular Economy - the main trend and EU requirements for closed raw material loop.

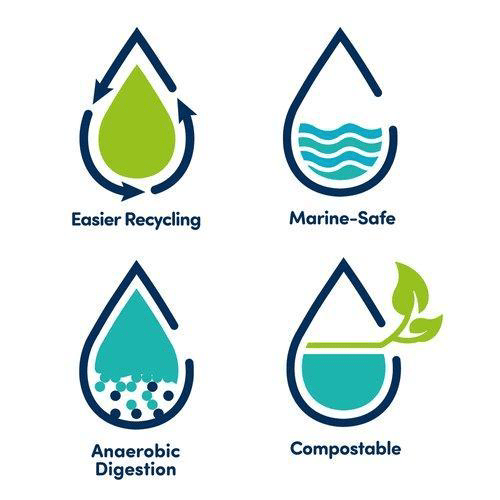

These materials already were successful in industrial trials for their RECYCLABILITY and BIODEGRADATION using standard recycling processes and equipment:

- with paper;

- with polymers;

- in wastewater;

- in compost.

Not ranked as harmful by EC Regulation 1272/2008 (CLP).

Included in the list of permitted food additives by Regulation (EC) No. 1333/2008 and of the Council on food additives (Е-1203).

«WatPac»

MAIN PROPERTIES

- High bi-axial strength and puncture resistance (approximately two and a half times as strong as high density PE film by equivalent weight).

- Direct food contact approved.

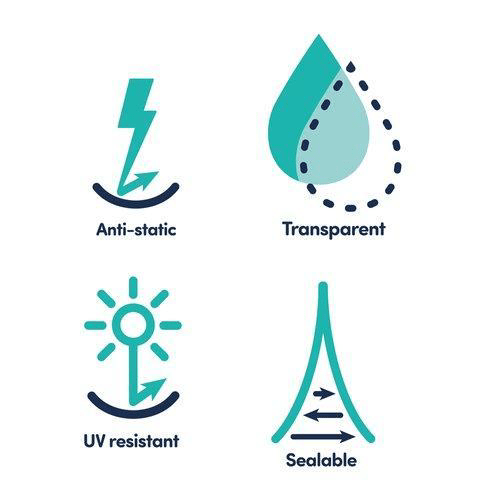

- Barrier to most solvents, petrochemical, grease and oil.

- Good oxygen barrier (0,1-0,9 cm³/m²/day on humidity 0%-50% for 25mkm film).

- MVTR – (12 g/m²/day on humidity 0% for 25mkm film).

- Capable of significantly extending the shelf life of certain foods due to its barrier properties and hydrophilic nature.

- Extrusion laminates do not have adhesive layers, so the material is easier to process and to recycle as there are no risks of degeneration of substances due the adhesive.

- The material has low values of haze.

- Sealing at the level of PE materials with higher toughness.

- Resistant to UV and not static.

«WatPac»

FUNCTIONALITY

- Easily recycled on paper mills by repulpation. Water solubility allow recycling in some special waste streams, such as paperboard re-pulping. Can be hot washed out and recovered or left.

- When it dissolved in pulp it is safely to environment and to the process. Water solubility allows easy separation of the material and its recovery from the general waste stream.

- Biodegradable, compostable, marine- and fresh- water safe.

- Subject to biological composting in an anaerobic environment.

- Water solution from used packaging well established as being inherently safe and non-toxic in the environment. It breaks down harmlessly into biomass, CO2 and water and the left fragments are ‘bioassimilated’.

- In the sea it will sink (film has density of 1.2), soften and break down completely over time.

- Toxicity tests water soluble materials show that it is marine biodegradable and marine safe to all regulated test fauna

«WatPac»

APPLICATIONS

AS A MONO MATERIAL OR FILM:

- Group packing

- Individual packing

- Window film for

- cardboard boxes

- sandwich boxing

- gift boxes

- boxes for confectionery

- Semi-finished product for the manufacture of disposable gloves, gowns, etc.

- Water-soluble packaging for single doses of detergents, fertilizers and other chemicals

«WatPac»

APPLICATIONS

AS A PART OF LAMINATE

- Packaging for confectionery products:

- Chocolate bars

- Group packing for bulk products

- Wrapping packaging

- Packing for dry pet food

- Packing for Groceries:

- Cereals

- Spices

- Flour

- Pasta

- And other

- Packing for snacks

- Frozen foods

- Bakery products